PCCA Journal|4

th

Quarter 2013

54

PLP has several U.S. locations that

manufacture, test, and design innovative

hardware solutions for the distribution and

transmission utility industries. For 30 years,

PLP has also offered fiber optic hardware

accessories for OPGW and ADSS cables. PLP

excels in customer service, emergency storm

response, engineered solutions, and techni-

cal product knowledge and support.

Contact a PLP representative for your next

project and find out why PLP products are

“The Connection You Can Count On.”

Corning Incorporated

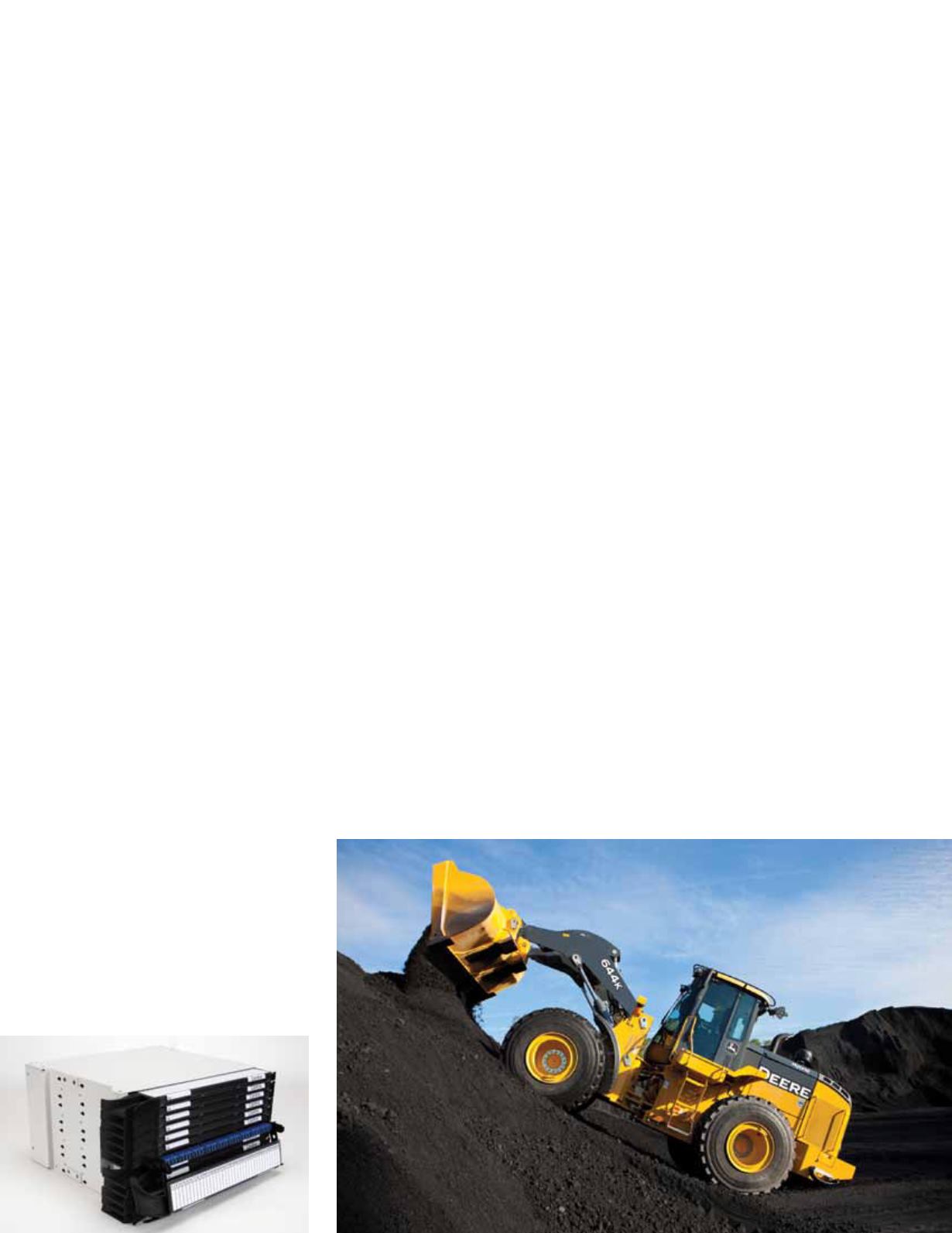

Corning Incorporated has introduced its

newly designed Centrix platform, an optical

connectivity solution that combines impres-

sive termination density with an intuitive

jumper routing system and superior cable

management.

Even with the increased density, the

Centrix platform provides an efficient use of

both jumper and cable routing space. The

customer can deploy more ports per square

foot and increase frame real estate utilization.

The Centrix platform meets the require-

ments of multiple application spaces—cen-

tral office, headend, fiber-to-the-x, fiber-to-

the-cell-site, and data centers—allowing

customers to use one platform across an

optical network. The single-cassette modular

design is ideal for efficient on-frame splicing

and optical device integration (i.e., wave divi-

sion multiplexer, splitters, and test ports).

The Centrix platform supports up to 4,320

LC or 2,880 SC connector ports per standard

7-foot frame. The “multiple path” jumper

routing system helps prevent jumpers from

piling up and entangling, thus managing

moves, adds, and changes more simply.

The Centrix platform is available in a

rear-cable access frame, which is compliant

to GR-449. It is also available in a front-cable

access frame, which enables back-to-back

frame configurations. Both options enable

deployment of more ports per square foot.

The building block for the Centrix platform

is the modular cassette, which contains 24

SC or 36 LC connector adapters. The cas-

settes can be ordered blank or pigtailed for

in-cassette splicing. A standard 4RU housing

will hold 12 cassettes. Housings can be or-

dered preloaded with cassettes and stubbed,

which can reduce installation time and risk.

John Deere

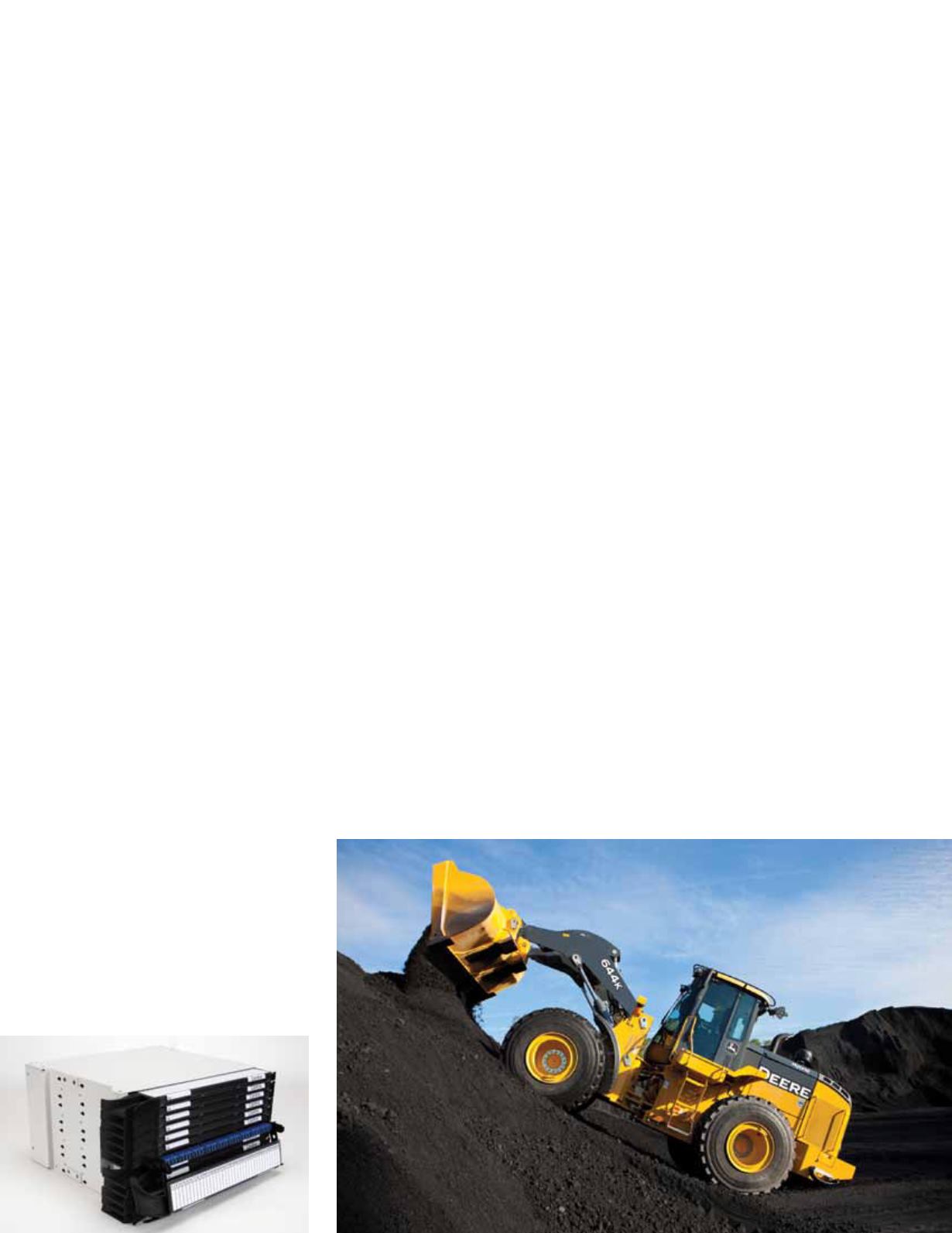

The new 644K Hybrid Wheel Loader from

John Deere is now available for value-driven

customers looking to lower owning and

operating costs. The 644K Hybrid utilizes two

sources of energy: diesel and electric. The

hybrid loader captures regenerated energy

as it’s being created and uses it to power the

machine.

The 644K Hybrid is equipped with a John

Deere PowerTech 6.8-L IT4/Stage IIIB engine

that runs at an operator-selected constant

speed from 900 to 1,800 rpm. The hybrid

boasts a net 229 hp and is equipped with all

the key features of the conventional John

Deere K-Series Wheel Loader line.

The machine’s hybrid technology delivers

performance that is equal to or better than

the conventional 644K, depending on the

application. The engine’s constant operating

speed maintains continuous hydraulic flow

at all times, which delivers crisp hydraulic

responsiveness and reduces cycle times.

The electric motor smoothly delivers torque

resulting in fluid operation and a smoother

ride. As a result, the 644K Hybrid delivers

optimal performance for novice and experi-

enced operators alike.

“With fuel prices on the rise, the 644K

Hybrid can reduce fuel consumption up to

25 percent, helping contractors lower their

daily operating costs,” said John Chesterman,

global product marketing manager for 4WD

loaders, John Deere Construction & Forestry.

“But there is so much more to the 644K than

fuel-efficiency. The hybrid’s features make it

easy to control, virtually becoming an exten-

sion of the operator.”

Another benefit of the hybrid design is

noise reduction on the jobsite. Since the

engine runs at a constant speed instead

of increasing and decreasing speed as the

machine is worked, the engine noise is con-

tinuous and therefore less noticeable to both

the operator inside the cab and bystanders

outside.

Ditch Witch

Drill operators will have a new horizontal

directional drill option from the Ditch Witch

organization this December: the Ditch Witch

JT60 All Terrain Horizontal Directional Drill,

which features a 200-hp, Tier 4i Cummins

Product Showcase

Continued from page 53