PCCA Journal|4

th

Quarter 2013

63

return possible for each item.

• Auctioneers - Reputable and highly skilled

agents make the entire bidding process

easier by helping buyers make good deci-

sions.

Overall, acquiring used machinery at

heavy equipment auctions gives both

buyers and sellers a feeling of confidence

based on the excellent reputation of the

auction company. This sales method makes

the entire process fast, easy, and efficient!

J.J. Kane auctions offer more options when

selling or buying equipment. The company’s

auction process is open and transparent and

can help contractors get the most out of the

auction on sale day.

Southwire

Nobody likes doing the same job twice.

That’s why Southwire saves the two-step for

the dance floor. The company’s innovative

SIM

pull

Cable-In-Conduit lets contractors do

just that, while saving time and money.

Southwire’s precision, cost-efficient manu-

facturing process assembles the cable and

conduit simultaneously, creating a trench-

ready product that is installed in one easy

step.

“Our technology-leading production lines

give us the flexibility to offer just about any

wire or cable inside the conduit to deliver

cost-effective solutions for every type of

electrical contractor,” said Southwire Sales

Manager Tom O’Brien.

SIM

pull

Cable-In-Conduit offers copper

and aluminum conductors for a wide range

of solutions including building wire, USE,

medium voltage, and specialty cables. The

CIC not only speeds up project time cycles,

but also prevents cable damage during

transport, staging, and jobsite storage.

“A lot of our customers

have virtually eliminated

wasted costs from replacing

damaged cable,” O’Brien

said.

SIM

pull

Cable-In-Conduit

applications include street

lighting, RV parks, sports

field lighting, airport light-

ing, parking lots, power

feeds, and temporary

power.

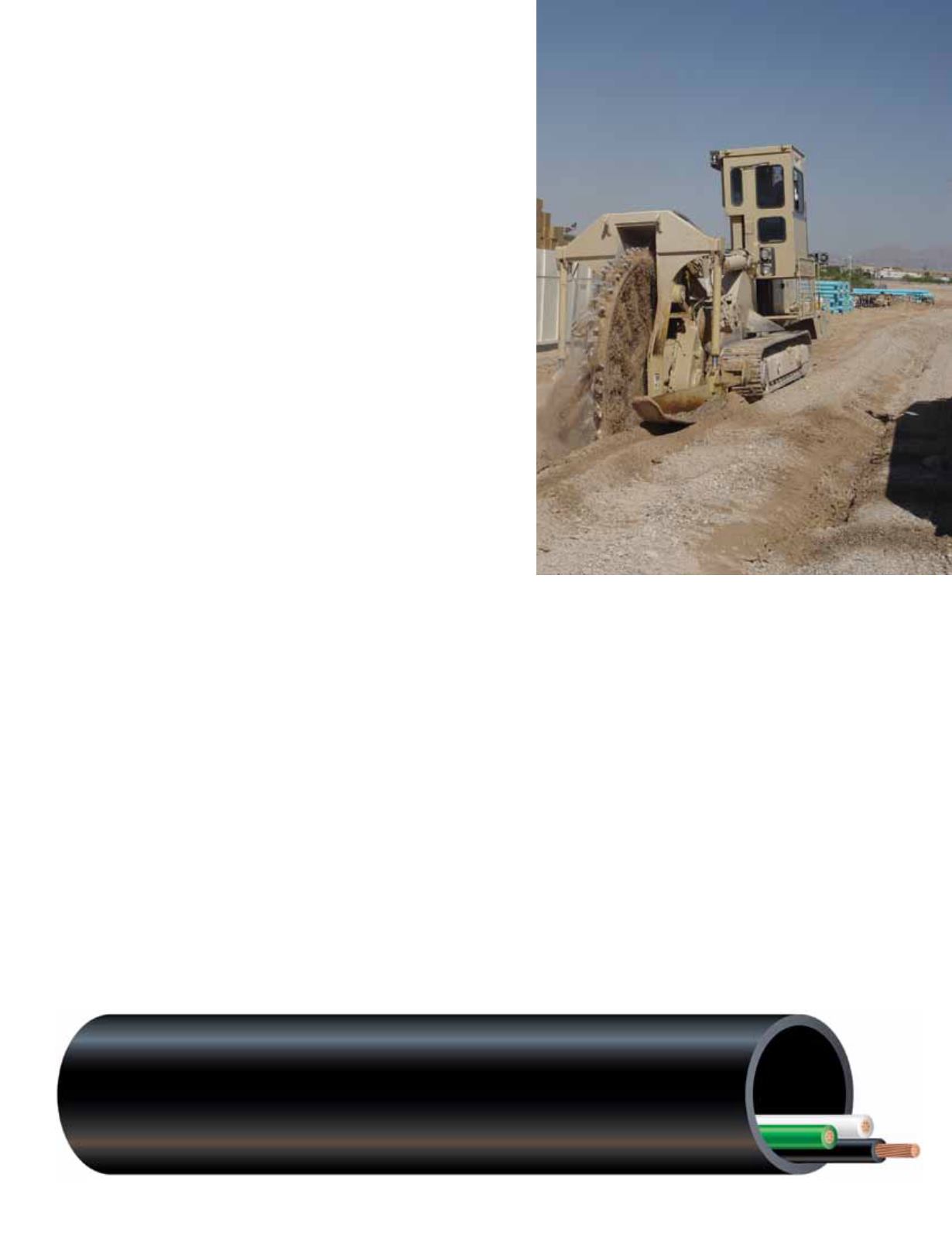

Tesmec

Since its foundation in 1984,

Tesmec USA, Inc. has been

building high performance

trenchers to operate day in

and day out under extreme

conditions. At its North

America corporate head-

quarters in Alvarado, Tex.,

Tesmec is fully integrated

in product design, fabrication, and precision

component machining, as well as the final

product assembly and the quality inspection

process.

The first model designed and produced by

Tesmec USA, Inc. proved such a success that

it soon became the standard for contrac-

tors around the world for hard rock cutting/

trenching.

Tesmec produces high quality trenchers

in four different configurations: rocksaw,

chainsaw, bucket wheel, and rock hawg.

Tesmec has built hundreds of trenchers

working on six continents, and the company

is constantly re-investing part of its profits

into R&D and new business ventures. Since

2012, it has entered the following sectors to

diversify its production and revenues: railway

equipment, farm drainage machines, and

multipurpose excavators.

The Tesmec Model TRS-1100A is a heavy-

duty rocksaw designed to cut trenches in

rocky terrain. Primary power is from a turbo-

charged diesel engine, and all functions of

the unit are hydraulically controlled.

The unit incorporates two-speed crawler-

drive, which provides infinitely variable

speed regulation whether traveling forward

or in reverse. The cutting wheel is hydrauli-

cally driven through flywheel gearboxes that

maintain consistent torque in most uneven

ground formations. Other major functions

are raising and lowering the cutting wheel

boom and stabilizers.

This machine is optimal for fiber optic

projects and other dry/wet utility jobs.

Continued on page 64