PCCA Journal|4

th

Quarter 2014

52

Product Showcase

Continued from page 51

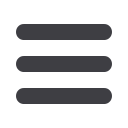

McLaughlin

The Vermeer by McLaughlin MEGA Vacuum

excavator line is designed to keep you on

the job longer with larger capacity spoil

tanks and fresh water options. The MEGA

Vacs can be equipped with three different

powerpacks to suit your application. All

are powered by a 99-horsepower Kubota

diesel engine and run a 1,200-cfm blower.

Powerpacks can be upgraded to add a DEEP

mercury (23-inch mercury) blower for fluid

management and HDD support or an Air/

Water combination powerpack with the

standard 1,200-cfm blower with 15-inches of

mercury.

These skid-mounted units have the ability

to arrive on a jobsite, pothole for existing

utilities, and then remove drilling fluids from

larger and longer bore projects. The MEGA

2000 skid-mounted vacuum excavator has a

99-horsepower Kubota diesel engine with a

1,200-cfm blower and features a 2,000-gal-

lon spoil tank and 925 gallons of fresh water

to ensure you have the power and capacity

required.

The MEGA 2600 skid-mounted vacuum

excavator is designed for fluid management

and HDD support for up to D100x120 class

rigs and maxi-rig jobs. The Mega 2600 is typi-

cally paired with PP100XT DEEP power pack

providing additional suction power with

the 23 inches of mercury DEEP blower for

increased fluid management capabilities. The

MEGA 2600 also features 300 gallons of fresh

water, making it a versatile potholing unit

when needed.

www.mclaughlinunderground.comUnderground Tools, Inc.

Underground Tools, Inc., headquartered in

Lino Lakes, Minn., is a world leader in the

manufacturing and distribution of ground-

engaging wear parts for the construction

industry, specializing in the development

of underground infrastructure through the

installation and remediation of utilities and

related activities.

The company was founded in 2003 by

partners that spent their entire careers in the

industry. UTI’s mission was developed based

on 100 percent customer satisfaction: Pro-

duce the highest quality products technol-

ogy will allow, offer at market-leading prices,

and provide customer service and support

that is second to none.

UTI manufactures a complete line of drill

pipe and complementary downhole tools

for horizontal directional drilling equipment.

Product line offerings include drill pipe,

sonde housings, pilot bits, backreamers, drive

chucks, starter rods, transition subs, wear col-

lars, jaw dies, adapters, and much more. Drill

pipe and tooling are available for all major

manufacturers’ drills, including Ditch Witch/

American Augers, Vermeer, Case/Astec,

Barbco, and Universal HDD.

UTI also manufactures fully integrated

digging systems and complementary

components for virtually every make and

model of trencher on the market, from the

smallest pedestrian units to the largest track

trenchers. Trencher chain of all sizes and

strengths is available, from 1.5- to 6.5-inch

pitch chains, which range in tensile strength

from 10,000 to more than 450,000 pounds.

Chain assemblies, complete with cutting

teeth, adapters, stabilizers, and hardware, are

built using special sequential pattern config-

urations designed to optimize productivity

based on application and ground conditions.

Sprockets, idlers, and rollers are engineered

specifically to match the trencher chains,

which allows for precise articulation and ex-

tended wear life. Digging systems and much

more are available for Ditch Witch, Trencor,

Vermeer, Case/Astec, Tesmec, Trench-Tech,

and many other trencher manufacturers’

equipment.

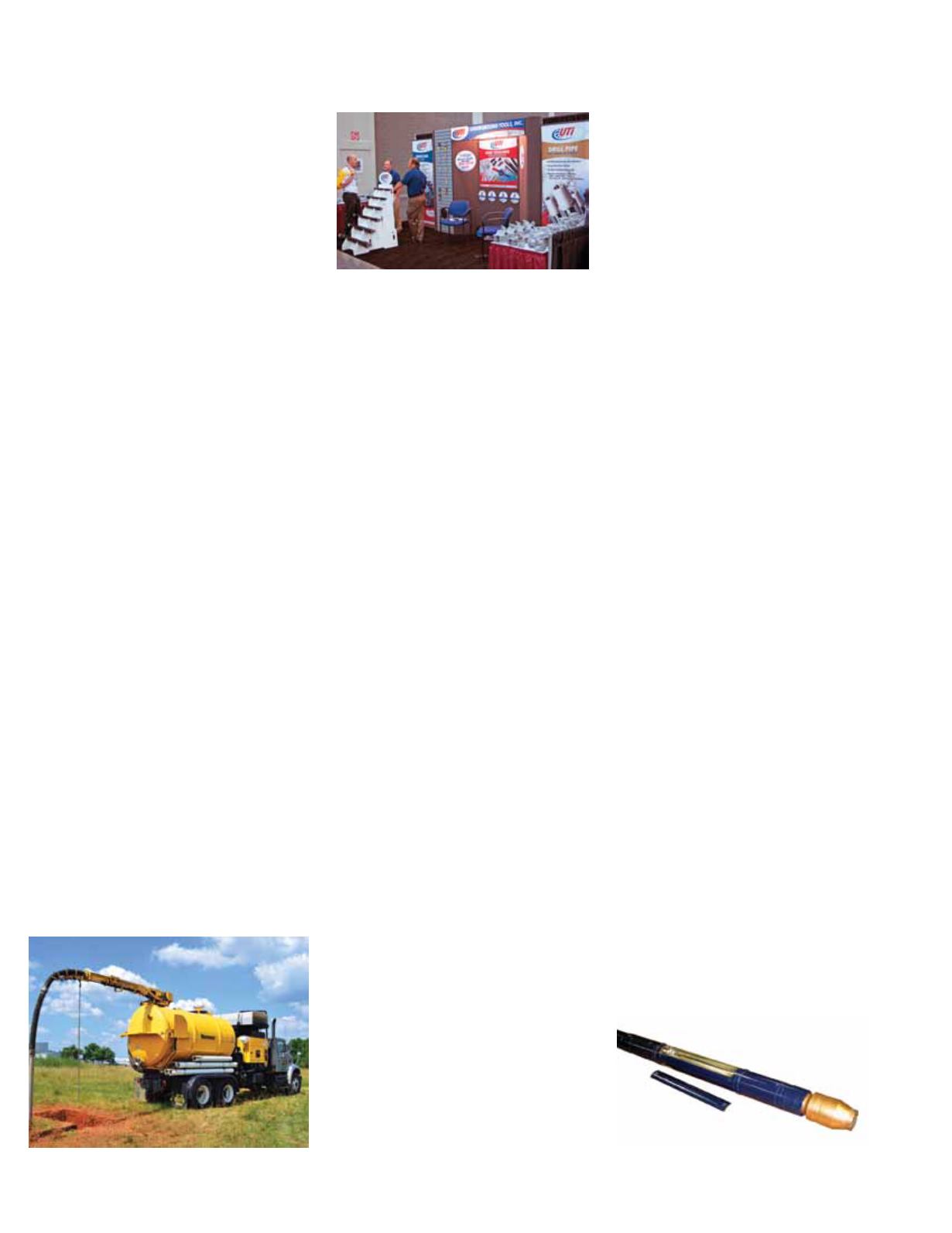

www.undergroundtools.comHunting Trenchless

After almost a year on the market, the

Hunting Trenchless M-Series Mud Motor

line continues to be a game-changer for the

directional drilling industry. The M-Series

design incorporates the sonde housing into

the bearing housing just 3-feet behind the

bit, giving the operator highly accurate track-

ing information.

“Unlike conventional mud motors that

position the sonde housing 20 or 30 feet be-

hind the drill bit, Hunting’s design provides

tracking information that is within 3 feet of

real time,” said Klane Kirby, general manager

of Hunting Trenchless. “These motors are also

engineered with a 1 1/2- or 2-degree bend in

the housing to provide effective steering in

even the toughest rock conditions.”

The M-Series Mud Motor is for use with

horizontal directional drilling equipment

with pullback ratings of 40,000 pounds and

higher. It has a diameter of 5 3/4 inches,

requires a bit of at least 6 3/4 inches, is 18

feet long with power section, and operates

on 150-gpm minimum mud flow.

Hunting mud motors have been on the

market for more than 10 years, with current

models incorporating features of the com-