PCCA Journal|4

th

Quarter 2014

40

Product Showcase

Continued from page 39

dustry, Global HR Research offers unmatched

adaptability, experience, and customer

service.

Global HR Research knows you need

more than screening and assessment. You

need pre-hire intelligence. That’s why GHRR

offers a robust set of screening and assess-

ment products. It’s a comprehensive set of

tools that will help you make better hiring

decisions and make them faster. When you’re

tired of your current approach to hiring, talk

to us about how pre-hire intelligence can

help you make smarter hires...today.

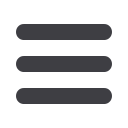

www.globalhrresearch.comSherman + Reilly

Sherman + Reilly has designed its Revolution

Series equipment around operator safety,

ergonomics, and environmental comfort.

The new Sherman + Reilly Revolution Series

P-1400X Single Drum Puller is a perfect

example of this. With a 14,000-pound pulling

capacity, the P-1400X also has additional re-

conductoring capabilities. This transmission

class puller utilizes an automatic horizontal

floating levelwind that permits overhead

rope retrieval with precision control.

One of the most important features of the

P-1400X is its Safe-Zone. The Safe-Zone Cab

employs a floor-to-ceiling polycarbonate

front window for maximum visibility while

providing superior protection against im-

pact. The cab includes climate control, a fully

adjustable ergonomic seat, and all required

electronic controls and gauges. The Safe-

Zone Cab is designed to reduce operator

fatigue and provide an “off-ground” envelope

for greatly reducing the risk of “touch poten-

tial” in energized environments.

The P-1400X is also equipped with an

ACG (advanced control group), allowing

for a single operator at a protected central

console to control payout speed, pulling

speed, levelwind controls, and jack position.

This puller comes with a 173-horsepower

industrial diesel engine capable of delivering

a full 14,000 pounds of line pull, rated at the

top of the drum. This machine also employs

a first-of-a-kind drum engagement system,

utilizing lateral sliding sides and drum

support rollers. These unique hydraulically

actuated articulating sides of the machine al-

low for easy changing of the drum to a metal

reconductoring reel. The fully hydraulic direct

drive system provides the operator with

precise and intuitive automatic drive/drum

braking. The P-1400’s tandem air brake axle

trailer is equipped with three hydraulic jacks,

an adjustable pintle eye, safety chains/hooks,

and U.S. DOT-approved LED lighting.

www.sherman-reilly.comAmerican Augers

There is a reason American Augers’ DD-440T

is a hot-selling maxi-rig! This track-mounted

horizontal directional drill offers 440,000

pounds of thrust/pullback and continues to

perform successful crossings for the pipeline

industry.

The carriage system is engineered with

a two-pinion drive with an adjustable force

limiter and a maximum carriage speed of 95

feet per minute.

The advanced rotary drive includes a three

pinion and gear drive that permits 60,000

foot-pounds of maximum rotary torque and

a rear-mounted mud swivel that provides up

to 650 gallons per minute of mud flow.

Other standard features include 10- to

18-degree drill angle, triple jaw wrenches

with a 12-inch separation, wrenches that

travel the full length of the thrust frame,

154,000 foot-pounds of maximum breakout

torque, 101,700 foot-pounds of maximum

makeup torque, removable wrenches for

lighter transport weight, and the ability to

utilize Range II drill pipe.

American Augers is a leading manufac-

turer of underground and utility construc-

tion equipment, including large directional

drills, auger boring machines, mud pump

& cleaning systems, trenchers, and tooling

& accessories. American Augers takes pride

in the support provided to its customers

around the world, 24-hours a day, 365-days

a year. Whether you are in need of additional

parts or encounter a technical support issue,

the dedicated service team is responsive,

knowledgeable, and customer-focused.

www.americanaugers.comPreformed Line Products

Preformed Line Products Company (PLP) was

founded in 1947 with the invention of the

helically preformed rod for the power indus-

try. Over the past 30 years, PLP has offered

copper and fiber optic closures, demarca-

tion, bonding, strand, and cable products

for communications markets, including fiber

optic hardware accessories for OPGW and

ADSS cables. Well-known brands include

COYOTE Closures, COYOTE Access Solutions,

ARMADILLO Stainless Closures, FIBERLIGN

Hardware, and GUY-GRIP Dead-ends.

PLP’s global reach and local focus strategy

for growth is supported by U.S. and interna-

tional locations. These facilities can produce

high-volume components as well as special-

ized products with responsiveness to local