PCCA Journal|2

nd

Quarter 2015

52

system with a 5.5-gpm, 3,000-psi water pump—more than

enough power and suction for large cleanup jobs around

directional drilling sites and municipal locations, plus soft

excavation tasks such as potholing utilities. Its autoclutching

feature disengages the water pump when water is not in use,

allowing full system power for suction.

Even with all of its power, the FXT60 is one of the quietest

truck vacs in the industry—only 82 dBA sound pressure—

thanks to a fully enclosed, insulated and lockable power

pack.

The FXT60 can be equipped with an optional hydraulic

boom that extends to 14 feet, which saves labor and time and

reduces operator fatigue. Other options include a choice of

tank configurations: a 500-gallon spoils tank with a 200-gal-

lon water tank or an 800-gallon spoils tank with two 200-gal-

lon saddle-style water tanks.

To accommodate international markets, the easily accessi-

ble, curbside controls can be configured for left- or right-hand

traffic, which enhances operator safety and convenience. The

FXT60 also has a standard hydraulic door that opens fully

horizontal to maximize the efficiency of spoils removal.

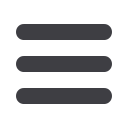

The AirStream Cable

Blowing Machine by GMP

G

eneral Machine Products Co., Inc. (GMP) recently

introduced the AirStream Cable Blowing Machine

to its line of fiber optic cable placing equipment.

Specifically designed to safely install micro fiber cable into

pre-installed 0.196- to 0.708-inch OD micro duct, the Air-

Stream will place 0.098- to 0.433-inch OD cable at speeds up

to 260 feet per minute. This, along with its low maintenance

and high reliability, make the AirStream an excellent value.

The AirStream incorporates a tabletop design with easy-

to-use ergonomic controls for one-person operation. The

unit uses a double belt drive concept, backed by the latest in

servo control technology, to provide a secure cable grip with

precise torque and speed control. The pushing force, up to 44

pounds maximum, can be adjusted to suit the cable stiffness.

The AirStream uses compressed air to install micro fiber

cable into micro duct in both indoor and outdoor environ-

ments. Its electrically operated, double belt drive can be

operated in forward and reverse to propel the cable through

the micro duct. An electronic monitoring system provides

read-outs of speed and distance and includes an emergency

stop capability.

With the purchase of any GMP fiber cable blowing ma-

chine, onsite training is provided at no additional cost. Rental

and rent-to-own programs are available.

Compressors are also available to accommodate GMP’s

complete line of fiber cable blowing machines. Note: the

AirStream requires 110/120 Volt AC service.

Condux Tesmec Names New

Technical Service Manager

Condux Tesmec announced the addition of James (Jimmy)

Curtis as its new Technical Service

Manager. Curtis will manage the

development of training materials

and deliver onsite training and

instruction to Condux Tesmec

customers throughout the United

States and Canada

“Training and customer support

are very important to Condux Tes-

mec. Having a skilled Technical

Service Manager in place will help

Condux Tesemc clients achieve

greater levels of proficiency and productivity in the field,”

said Director of Sales and Marketing Jeremy Smuder.

Curtis brings over 20 years of customer support in the

development and administration of training and instructional

materials.

Sherman + Reilly Adds

P-2000X to Revolution Series

S

herman + Reilly, a leading manufacturer of power

line stringing and installation equipment, continues

to drive innovation with an addition to its Revolution

Series, the P-2000X Single Reel Bullwheel puller.

This new transmission class puller is equipped with a

175-horsepower industrial diesel engine capable of deliver-

Member News

Continued from page 51