PCCA Journal|2

nd

Quarter 2015

56

Member News

Continued from page 55

ments will now help CIPP rehabilitation contractors access

projects in some of the country’s most restrictive markets.

HydraLiner is a complete CIPP system for lateral pipe reha-

bilitation with inversion drums, wet out tables, and trailers.

The NSF International and ICC-ES certifications specifically

endorse the safety and quality of HydraLiner consumables.

These include liners for rehabilitation of pipes 2 to 12 inches

in diameter and a variety of epoxy resins for different job

requirements and working conditions.

The HydraLiner product line had already been certified

to ASTM F 1216 standards. Such independent, third-party

certifications are referenced by federal, state, and municipal

regulatory agencies during the approval process prescribing

which products may be used in projects under a particular

agency’s jurisdiction.

The endorsements also reassure project stakeholders of the

safety, durability, and quality of the products. “These certi-

fications are additional reassurance from two independent,

highly regarded testing agencies that only the best materials

are being used in their projects,” said Matt Gabrielse, certifi-

cation manager for the HydraLiner product line.

The HydraLiner system can be used in a variety of CIPP

applications including sanitary sewers, storm sewers, process

piping, electrical conduits, and ventilation systems. The

system repairs cracked or broken pipes, eliminates future root

intrusion, bridges fractures and gaps, and stops both infiltra-

tion and exfiltration. The system is effective with most pipe

materials including clay, cast iron, PVC, ABS, and concrete.

The system will even rehabilitate pipes whose lines contain

bends up to 90 degrees and transition from one pipe diameter

to another.

The Value of Southwire’s

Intelligent Grid Systems

S

outhwire Energy Division’s new line of Intelligent

Grid solutions combines innovations in monitoring

and analytics to provide wide area awareness of grid

assets. Solutions include line and substation monitoring,

which collects, communicates, and processes data from mul-

tiple sensors to improve reliability, capacity, and generation

dispatch.

“We developed Southwire’s Intelligent Grid solutions to al-

low utility providers to constantly monitor systems from vir-

tually anywhere by sending real-time data directly to them,”

said Mark Lancaster, PE, Southwire Director Intelligent Grid

and Energy Solutions. “This allows utilities to know what’s

happening on the system at all times to ensure reliability and

optimize asset utilization.”

To do this, the Southwire Intelligent Grid solutions col-

lect and aggregate data from sensors and weather nodes

and transmit that

information to the

utility via a cellular

or utility-specific

communication

network. The data

is processed using

Southwire algo-

rithms and inter-

faced into the utility

data and control

systems. Monitoring

options include sag,

temperature, and

rating for conduc-

tors, degradation of

conductor connec-

tors, and likelihood

of flashover due to

contamination for

insulators and sub-

station equipment

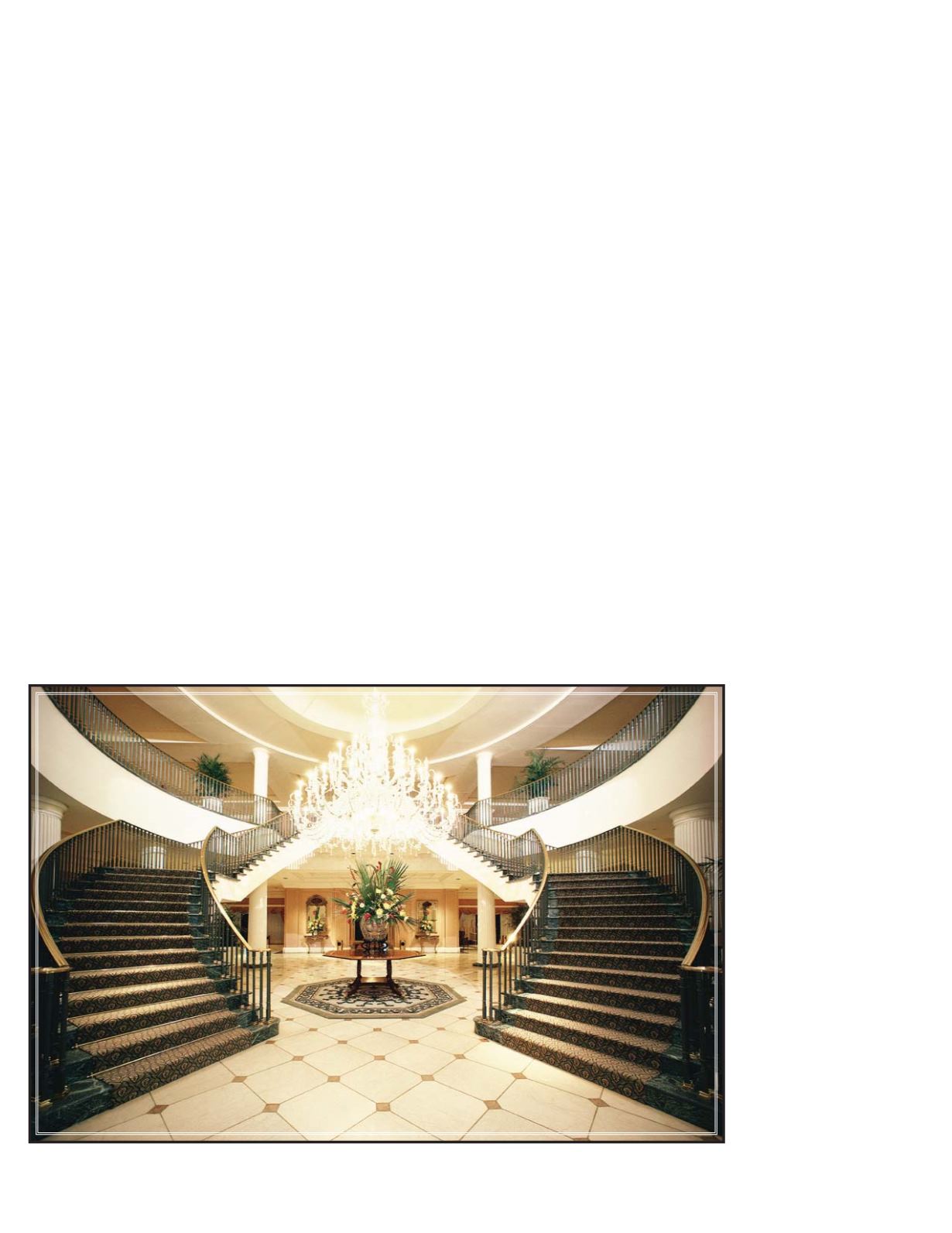

2015 PCCA Mid-Year Meeting

Belmond Charleston Place

Charleston, South Carolina

September 23-26