PCCA Journal|3

rd

Quarter 2015

47

Member News

Subsite Electronics

Unveils NewWebsite

S

ubsite Electronics, a Charles Machine Works company,

has unveiled its new mobile-friendly website. Guided

by customer input, the site provides utility, pipeline,

telecom, and other underground construction professionals

easy access to information regarding Subsite’s unique selec-

tion of underground awareness products for enhanced jobsite

safety and productivity.

The new responsive site is available via desktop, laptop,

tablets, and mobile devices, giving users convenient and

quick access to information, whether they’re on the jobsite

or at the office. The site also includes time-saving software

updates for Subsite Electronics products. Users can easily

access a find-a-dealer tool to locate the nearest Ditch Witch

dealership, from which Subsite products are sold.

The new site is an extension of the Subsite Electronics

commitment to providing innovative, integrated, and reliable

electronics to help facilitate the installation and maintenance

of buried pipe and cable. Through decades of innovations,

the company delivers a comprehensive suite of electronic

products serving the underground construction professional,

including HDD guidance systems, utility locators, and equip-

ment machine controls.

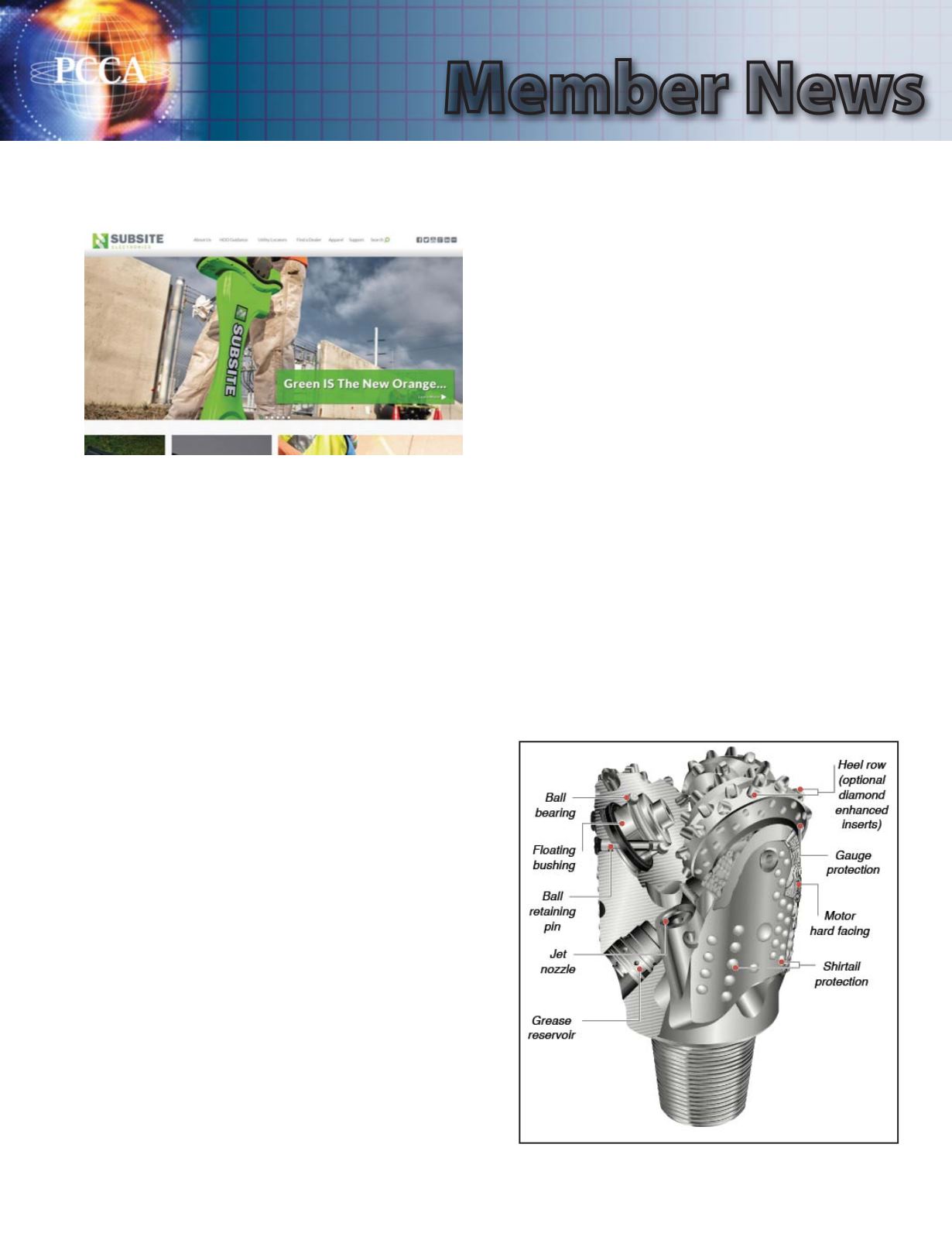

Roller Cones Need Love Too

The following tool tips were provided by PCCA member Radius

HDD.

With the increasing power and capability of today’s HDD

rigs, more boring contractors are turning to roller cones to

succeed in hard conditions.

Whether it’s a Single Roller Cone pilot bit or a Hole Opener

designed with roller cone cutters, keeping the internal bear-

ings greased is often overlooked. Many HDD operators are

unfamiliar with roller cone technology and not aware that

roller cones can (and should) be greased.

The two most common roller cones used in HDD are

Sealed Roller Bearings and Friction Bearings; both require

greasing for proper operation.

A word of caution: Over greasing a sealed bearing roller

cone can result in blowing the seal and damaging the cone.

Knowing when to apply grease is important!

If the cone rolls somewhat freely, it is likely the grease has

broken down. A new application will protect and extend the

life of the internal bearings.

Both bearing and friction roller cones have a grease port

located near the bearing cavity. It is usually plugged with a

set screw. If the bit is worn, it might take a little searching to

find.

Remove the plug and screw in a grease zerk fitting com-

mon with your grease gun. Apply 2 to 3 pumps of grease

and check the results on the “roll” of the cone. It should be

more firm and require additional effort to spin. If it is still too

loose, apply two more pumps of grease and check the spin

again. Be sure to remove the zerk and re-seal the cavity with

the set screw. Contamination (dirt and fluid) and friction

(heat) are the two primary causes of premature cone failures.

Reminding your crews to clean and grease your tools

Continued on page 48